Welcome to the manufacturer of sustainable 100% polypropylene knitted fabrics and garments

Coloring Process of Polypropylene: Enhancing Aesthetics in the World of Synthetic Fibers

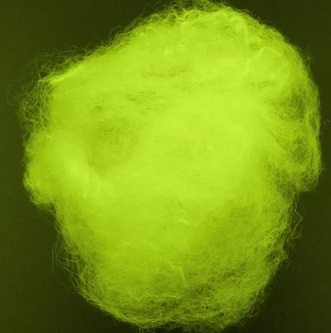

Polypropylene (PP) is a versatile synthetic fiber widely used in various industries due to its exceptional properties. While PP is naturally colorless, it can be effectively dyed to achieve vibrant and attractive hues。This article aims to explore the coloring process of polypropylene, shedding light on the techniques employed to enhance the aesthetics of this remarkable synthetic fiber.

Dyeing Methods for Polypropylene:

Solution Dyeing:

Solution dyeing, also known as mass or pigmentation dyeing, is a popular technique for coloring polypropylene.In this process, color pigments are added directly to the PP polymer melt before extrusion. The pigments become an integral part of the fiber,resulting in excellent color fastness throughout the life of the product. Solution dyeing offers vibrant and uniform coloration, even in deep or dark shades.

Top Dyeing:

Top dyeing, also referred to as package dyeing, is another method used to color polypropylene fibers. In this technique, the fibers are wound onto a perforated dye package or beam, which allows the dye to penetrate the fiber. The dye liquor is circulated through the package, ensuring uniform color distribution. Top dyeing is commonly used for multi-color or variegated designs, enabling precise control over color placement.

Printing:

Polypropylene fabrics can also be printed using various methods, including screen printing, heat transfer printing, and digital printing. Printing allows for intricate and detailed designs to be applied to the fabric's surface. In this process, colorants are applied to the fabric using specific techniques, resulting in patterns,motifs, or graphics. Printing offers versatility in design and allows for customization according to market trends and consumer preferences.

Challenges in Polypropylene Dyeing:

Dyeing polypropylene can present some challenges due to the fiber's hydrophobic nature. PP has a low affinity for water, making it resistant to traditional dyeing methods.

However, advancements in dyeing technology have addressed these challenges, enabling effective coloration of polypropylene fibers.

Advantages of Colored Polypropylene:

Aesthetic Appeal: Colorful polypropylene fabrics offer visual appeal and versatility, allowing for a wide range of applications in the textile industry。Enhanced Marketability: Colored polypropylene products cater to consumer preferences for vibrant, eye-catching garments and textiles. The availability of a broad spectrum of colors enables manufacturers to create attractive and fashionable products.

Brand Differentiation: By utilizing colored polypropylene, manufacturers can differentiate their products in the market, thereby enhancing brand recognition and customer loyalty.

Durability: The colorfastness of dyed polypropylene ensures that the vibrant colors remain intact, even after prolonged use and numerous wash cycles.

Polypropylene, a remarkable synthetic fiber, can be effectively colored to enhance its aesthetic appeal. The coloring process involves techniques such as solution dyeing, top dyeing, and printing, which allow for vibrant and uniform coloration. Colored polypropylene fabrics offer advantages such as enhanced marketability, brand differentiation and durability. As technology advances, the dyeing of polypropylene continues to evolve, opening up new possibilities for creative and visually appealing applications in the textile industry.