Welcome to the manufacturer of sustainable 100% polypropylene knitted fabrics and garments

Understanding Polypropylene Staple Fibers: A Versatile Material for Various Applications

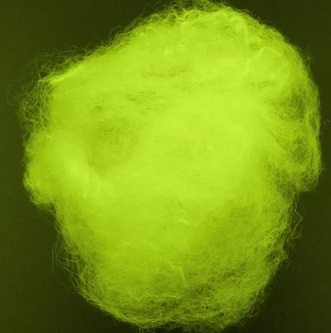

Polypropylene staple fibers (PPSF) are single fibers that offer a wide range of benefits and applications. Derived from isotactic polypropylene chips through a melt spinning process, these fibers possess exception properties that make them suitable for diverseindustries. This article aims to provide a comprehensive overview of polypropylene staple fibers,highlighting their manufacturing process, key features, and applications.

What are Polypropylene Staple Fibers?

Polypropylene staple fibers are individual fibers that enhance the crack resistance, impermeability, anti-wear ability,anti-freezing ability, and anti-explosion ability of materials such as concrete. They also improve the workability of concrete, making it easier to handle during construction projects. These short fibers are evenly distributed within mortar and concrete, ensuring the integrity of the structure and preventing it from shattering into fragments when impacted.

Benefits and Applications:

Enhanced Durability: The addition of polypropylene staple fibers significantly extends the service life of structures by reducing the corrosion of steel bars.This, in turn,reduces maintenance costs and enhances the overall durability of the project.

Anti-cracking and Anti-wear Properties: Polypropylene staple fibers are commonly used in anti-cracking putty powder,thermal insulation mortar, and concrete.They improve the toughness, impact resistance, and wear resistance of these materials, enhancing their overall performance and lifespan.

Moisture Permeability and Quick-drying: These fibers offer superior moisture permeability and quick-drying properties,making them ideal for applications where moisture control is crucial. Additionally, they exhibit good combability and spinning performance, allowing the production of soft and tough fabrics.

Versatile Applications: Polypropylene staple fibers find applications in various industries. They are used for manufacturing air filters, water filters, industrial fabrics, woven and non-woven carpets, upholstery, carpet backings, and more. Their low specific gravity, dimensional stability, and excellent recovery properties make them highly desirable in different settings.

Polypropylene staple fibers are a versatile material known for their numerous benefits and applications. Their manufacturing process involves converting polypropylene resin into fibers through a melt spinning process. These fibers offer properties such as high insulation, chemical resistance, lightweight, and resistance to abrasion, making them suitable for a wide range of finished product applications. As the demand for synthetic fibers continues to grow, the market share of polypropylene staple fibers is increasing steadily. Embracing the unique properties of polypropylene staple fibers opens up new possibilities for innovation and product development across various industries.